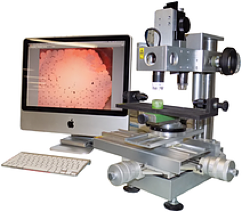

Test resources

Wires analysis

Our analysis laboratories allows to get all the qualifications required in the enamelled wires industry.

Major magnet wires manufacturers have already used our knowledge and the qualifications conducted in the past used baseline today.

This level of expertise has allowed AMR to be present in sectors such as Nuclear, Energy, Automotive and Aerospace.

Provided test

Tests are driven according to the standards (IEC 60851 - IEC 60216, …) or to the customers specified needs.

Why wires analysis ?

Standard tests managed by wires manufacturers have shown their limitations as final customers can obviously notice.

Analysis and tests processes must be defined in order to satisfy the specific customers needs. Tests procedures can be managed with a confidentiality contract with final customers or wires manufacturers.

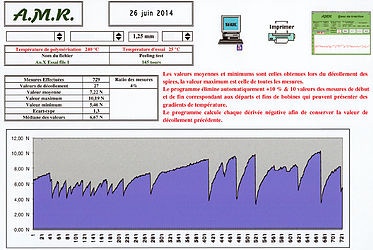

Test of residual bonding

Connection

It is important to remember that an electrical connection is a set between :

- An unanemelled standard cable

- A terminal of dimensions corresponding to the cable

• A crimping die which corresponds to the cable and to the terminal

Sections of our Litz cable do not match the standard terminals which are associated with them.

The use of a standardized terminal and a non-standard Litz wire corresponds to an "invention" that must be qualified with :

- Mechanical tests

- Electrical tests

- Visual tests

Find all the test and the test protocol in the book " Methodology"

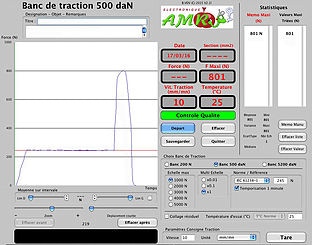

Destructive test to validate the process (matrices and crimping tools).

There are different traction protocol that are prescribed by setting standards.

Tensile strength is inversely proportional to the contact resistance.

This correlation is important, but it is not sufficient to judge the electrical characteristics of a connection.

Methodology

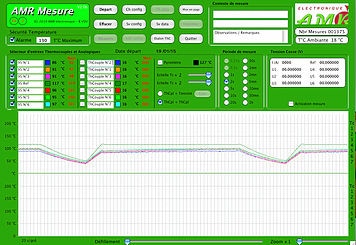

These tests simulate stresses of thermal cycling on a connection.

This determine the evolution of the contact resistance at the crimping.

The main constraint during a cyclic heating is the dimensional variation between the connector and the cable.

It is this expansion that generate chemical reactions (oxidation) at the constriction surfaces.

As the temperature increases, the oxidation rate will also increase.

Copyright © 2015 AMR Electronique. All Rights Reserved.